The i-Button redefines durability and design in denim hardware.

When Denim Meets Industrial Aesthetics: How One Button Rewrote Fashion Rules

From Levi’s original five-pocket blueprint to today’s oversized streetwear silhouettes, denim has always been more than fabric—it’s a cultural artifact. And at the heart of its evolution lies a tiny but mighty detail: the front button. Often overlooked, this small metal component has quietly shaped both function and fashion across generations.

In recent years, as consumers demand not just style but substance, functional hardware has emerged as a silent differentiator among premium denim brands. It’s no longer enough for a button to simply “hold.” It must endure, enhance, and even express identity. Enter the i-Button Jeans Head Button—a fusion of industrial resilience and refined design that’s changing how we think about closure systems in casual wear.

Engineered to move with you—tested through deep squats, wash cycles, and daily grind.

More Than Just “Holding On”: The Mechanical Philosophy Behind i-Button

The i-Button isn’t static—it’s dynamic. At its core is a precision-engineered rotary shaking mechanism paired with a straight nail shank. Unlike traditional flat-backed or threaded buttons that concentrate stress on a single point, this innovative structure allows controlled movement during body motion, effectively distributing tension across the fabric.

Imagine sitting down, bending over, or pulling on tight jeans. Conventional buttons often strain, warp, or pop off entirely under repeated stress. But the i-Button’s rotating base absorbs kinetic energy, reducing localized pressure by up to 40% compared to standard rivet-style closures. This isn’t theoretical—real-world testing shows it surviving over 10,000 simulated wear-and-wash cycles without failure.

Laundry day? No problem. High-speed spin cycles, aggressive detergents, and hot water don’t compromise its integrity. Whether enduring mechanical agitation or human motion, the i-Button stays put—where it should be.

The Quality Code Behind Factory Direct Supply

Beneath the sleek surface of every i-Button lies a rigorous seven-stage manufacturing process. Starting with high-grade zinc alloy die-casting, each unit is formed under intense pressure to ensure structural uniformity. Then comes sequential polishing, multi-layer electroplating (including nickel and eco-friendly top coats), and laser-inspected finishing.

This level of control is why forward-thinking designers are bypassing middlemen and sourcing hardware directly from production lines. By partnering at the source, brands gain tighter quality oversight, faster prototyping, and greater customization flexibility—all while reducing lead times and hidden costs.

Precision craftsmanship visible in every curve and edge.

Built for Stretch: Meeting the Demands of Modern Denim Fabrics

Today’s denim is no longer rigid. With spandex-infused weaves dominating the market, garments stretch, rebound, and flex like never before. Yet most legacy fasteners were designed for stiff cotton twill—not elasticated performance fabrics.

That mismatch leads to one common issue: button blowouts. As stretch denim returns to shape after movement, conventional riveted buttons resist the fabric’s natural rebound, creating micro-tears that escalate into full detachment. The i-Button solves this with its dynamic fit system—the rotating head accommodates fabric recovery, maintaining secure attachment without compromising the surrounding material.

The Hidden Language of Style: Design That Speaks in Details

Fashion is felt in moments: the tug of a pocket flap, the glint of metal against indigo, the subtle arc of a button’s crown catching light. The i-Button’s domed top isn’t just ergonomic—it’s aesthetic. Its smooth curvature guides the eye, enhances tactile experience, and creates a refined contrast against textured denim.

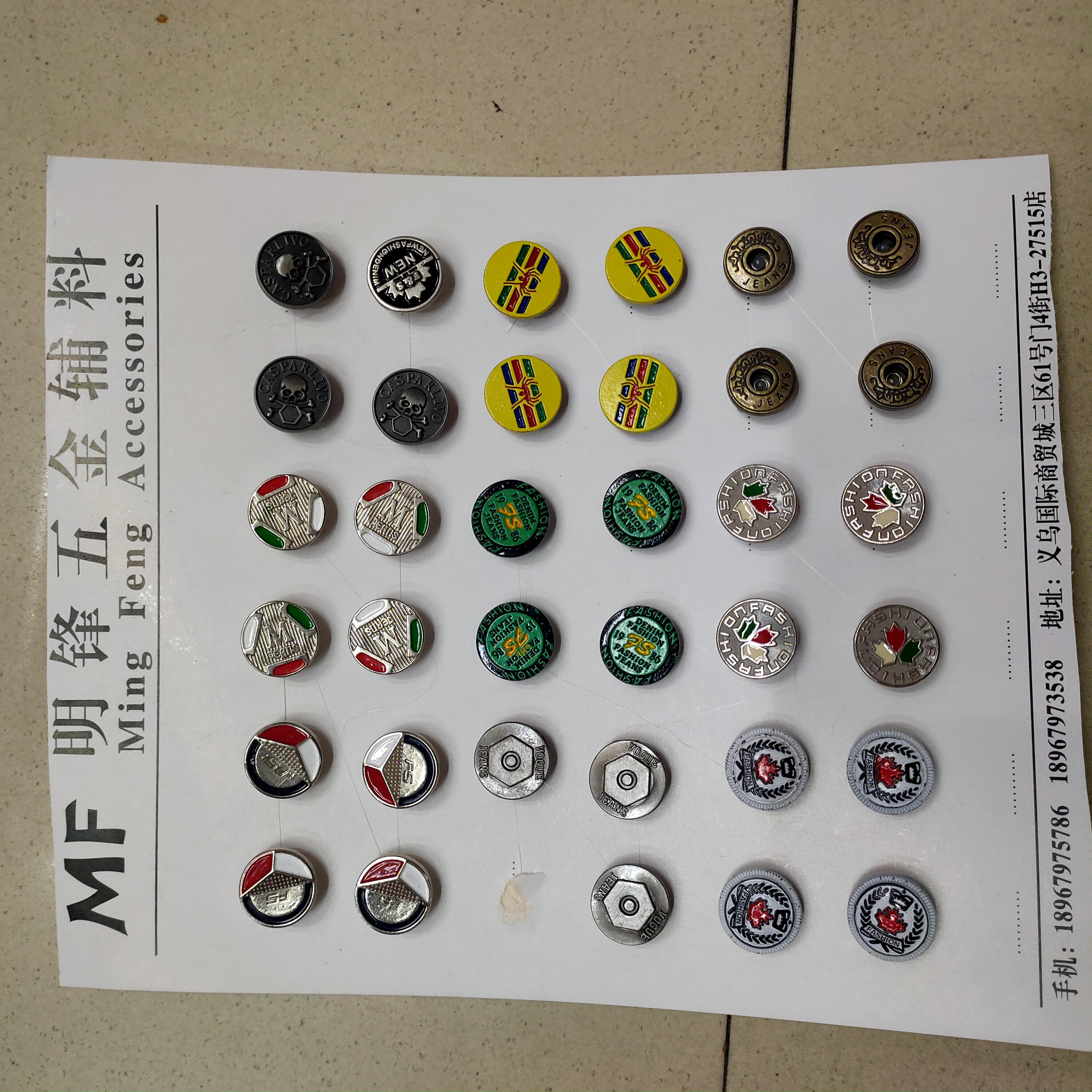

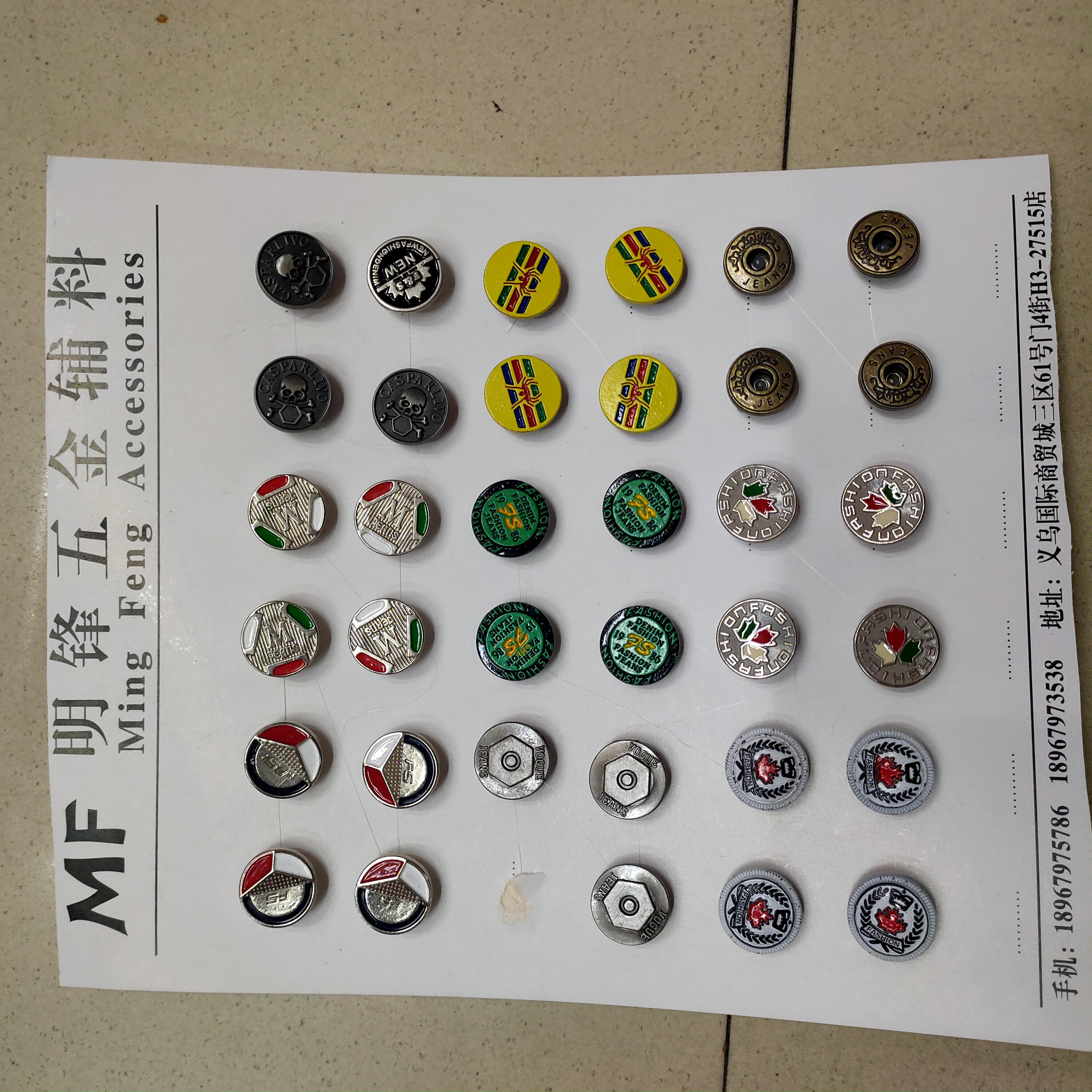

And because branding lives in details, the i-Button offers customizable plating finishes: matte gunmetal for minimalist edge, vintage bronze for heritage warmth, and mirror-polish silver for bold statement-making. These aren’t mere color options—they’re brand signatures waiting to be claimed.

A Choice That Defines Longevity: Why Smart Brands Think Beyond Unit Cost

Selecting a button is not just a procurement decision—it’s a commitment to product lifecycle. While some may focus solely on upfront price, savvy manufacturers calculate total ownership cost: including return rates, customer complaints, and brand reputation erosion due to premature failures.

One rising streetwear label discovered this firsthand. After switching to i-Button across their core denim line, they saw a 3x increase in customer mentions of “durable” and “well-made” in reviews. More importantly, warranty claims related to fastener damage dropped by nearly 70%. In an era where word-of-mouth travels fast, such shifts can define brand perception.

The Future of Denim Lives in the Seams—and Snaps

As sustainability reshapes fashion, questions arise: Can metal components be reused? Could modular design enable repair, upgrade, or recycling? The i-Button’s robust construction and standardized mounting suggest potential beyond its current role. Imagine future wardrobes where buttons aren’t discarded with worn-out jeans—but salvaged, repurposed, even celebrated as wearable tech anchors or accessory connectors.

The next revolution in denim won’t come from a new wash or cut. It will emerge in the quiet strength of a well-placed button—one that holds firm, looks sharp, and lasts longer than expected. The i-Button isn’t just keeping up with change. It’s helping sew the future together.